Hey gang,

as usual a long read incoming, scroll down for tl;dr.

First of all, we want to thank you for your patience, it’s a longer ride than expected. Now 10 months after the start of the production, we are getting close to finalize the production of Werk One R.1.

Where is my Werk?

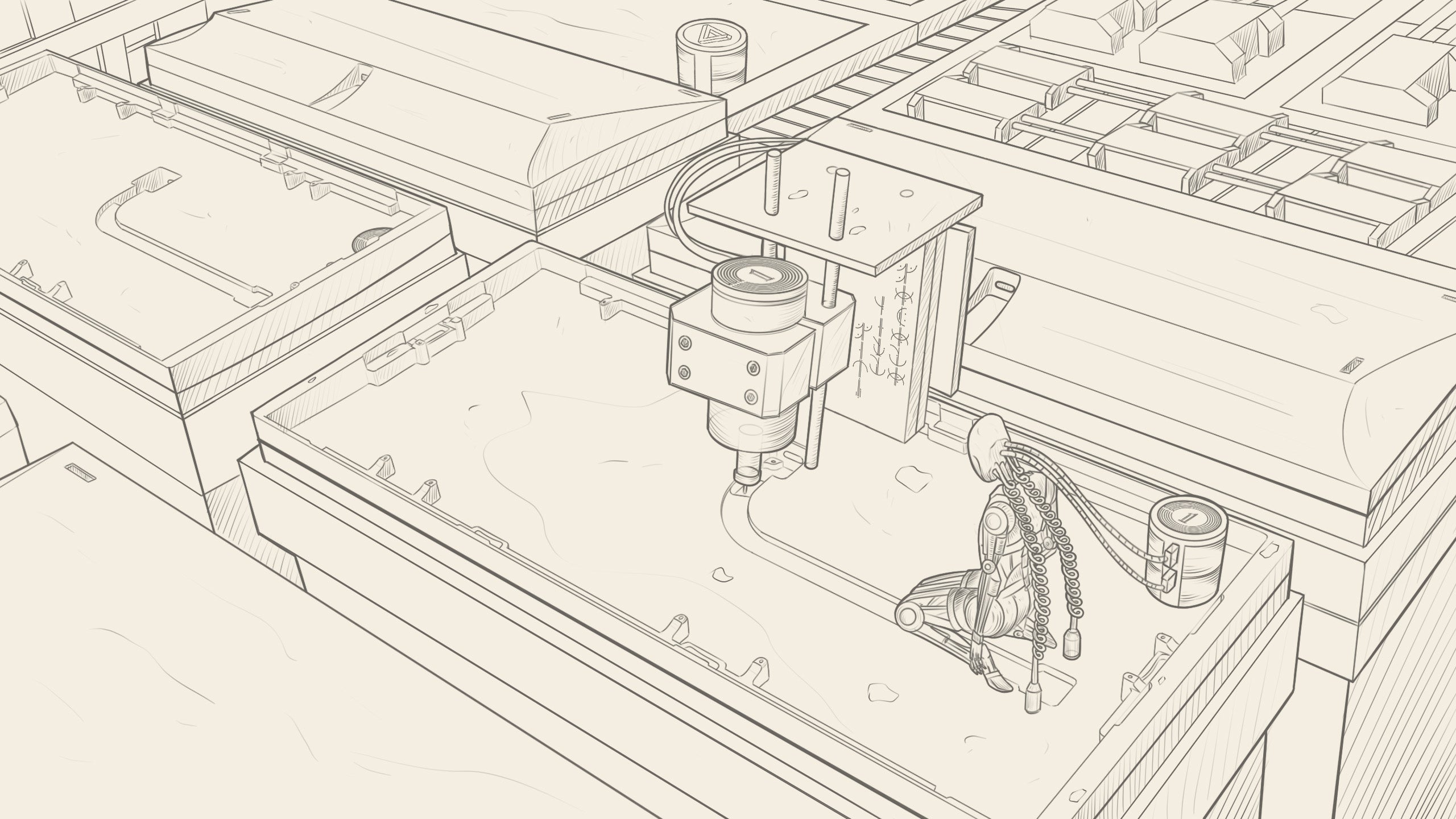

The CNC and the coating of the metal parts is finished, all copper units are now finished too. The production of PCBs is finalized, those are tested and passed QC. Here some freshly shot copper and brass pics from our manufacturing partner:

During the factory QC in August, it became apparent that large percentage of polycarbonate tops had issues. The problem was the polycarb block that the factory received and some flaws became apparent only during the QC. We had to reorder polycarbonate and completely reproduce the affected polycarbonate units, which was done in September. This wasn’t our only setback with polycarbonate, the units came out well when we first manufactured and stored them, but during pretty big temp fluctuation in this time of the year, we found another issue. The threaded inserts for both badges and future modules have been a bit too many for polycarb, which led the polycarbonate to be prone to cracking. This might have become an issue during shipping from our factory to Germany and then to you. To prevent this, we are redoing the threads in polycarbonate, reducing the number of threaded inserts.

Apart of that we placing the final serialization engravings on our badges.

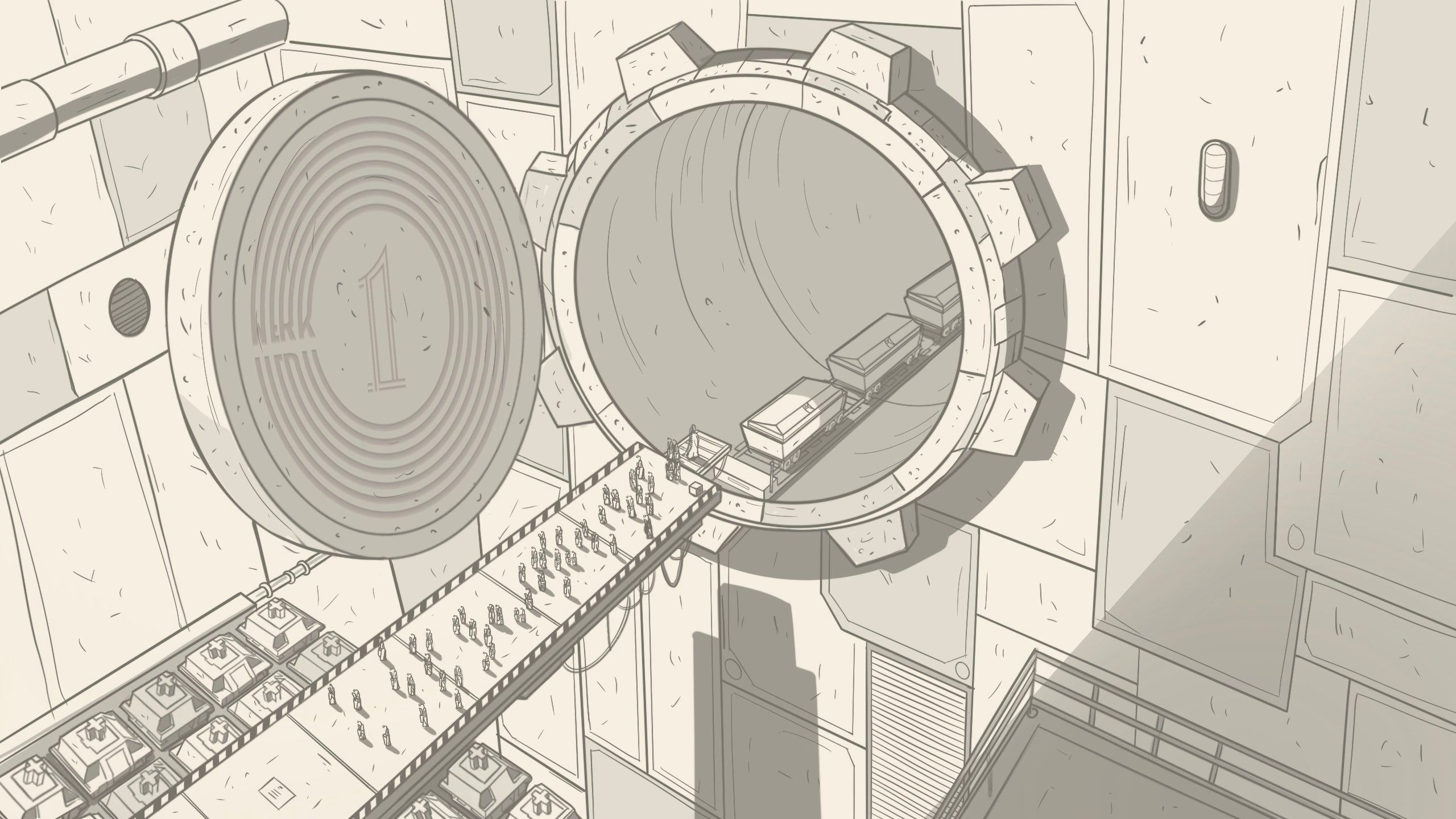

Right now, those last units are being finalized. After that the boards will be packed up and shipped to us. We are expecting the factory to ship to us to Germany first weeks of November. After that the boards will be QC in our warehouse in Germany and shipped to you.

What about the MKEU buyers?

Right now, MKEU buyers are looking at a similar ETA. Despite the problems that MKEU had with every single payment step we had to do together which definitely impacted the production timeframe, MKEU is currently almost on track just being 1 smaller packaging payment behind. This should not affect the fulfillment. Most of the major current payments have been placed by MKEU. Personally I am rather confident about the QC process at MKEU, despite all the management issues they faced this year, they got a very experienced QC team that fulfilled many big runs.

Should you still have any unanswered MKEU tickets, kindly send me your ticket number per DM and we forward your request directly to their support team with a big fat reminder. Saying this, we don’t have any more insights into how MKEU manages their business, nor we have any control over it, what we can do is, try our best to have your back.

So, what’s our ETA?

We very much hope, that we start shipping out the first units this year, much will come down to the shipping speed to Germany and the customs process. We will keep you updated on it in the Werk One channel as usual with our smaller updates.

In preparation for shipping:

Over the course of last few months, we received plenty of address change requests. Each request was answered with a confirmation of address change by us. Still there is a chance that a ticket was missed. If you haven’t got a confirmation from our end – depending on your mood, wave or throw something heavy in my direction, I will look into that asap personally.

Should you require an address change, this is the best time to inform us. There will be another last call for that before the fulfillment begins.

Since we are getting A LOT of requests:

Yes, there will be some extras. We ordered a fair number of extras, though some of them might be used during QC. We will give you a definitive number after fulfillment.

Considering the interest, yes there will be Werk One R.2 probably next year.

In other news:

Werk Triad is in prototyping, we expect the first proto before the end of the year!

We are looking at 2024 for the Werk Triad R.1 likely together with Werk Instrument, to ensure that the matching of Instrument colours and coatings and corresponding Triad variants is ideal we decided to produce them together.

Currently we are working on new finishes like brushed aluminium and dual anodizing techniques, more about it soon!

Since you wisely ignored the wall of text above:

tl;dr

- Remaining Werk One Copper cnc and coating is finished and passed the factory QC

- PCBs are finalized and passed the QC

- We ran into issues with polycarbonate that are mostly resolved now

- We expect the factory to ship the units to us first weeks of November

- Despite plenty of hook ups that delayed the production, MKEU is back on track

- We hope to start shipping this year, much will come down to shipping speed to Germany and the customs process

- If you need your shipping address changed, now is a good time. If you requested address change and the request remained unanswered – mea maxima culpa, please leave us a ticket through the page contact form or dm me on discord.

- There will be extras

- There will be R.2, likely 2024

- Triad is in prototyping with GB target sometime 2024

- Instrument will be released alongside with Triad 2024

- We are working on new finishes and coating techniques for future runs

Thanks for your patience everyone!

Zaum out